Oil & Gas operations demand always-on, high-bandwidth connectivity — whether onshore or offshore. iNet’s technology ecosystem delivers enterprise-grade communication, security, and visibility across the entire energy value chain — from rig to refinery. Powered by Continuum™, Sentinel™, and Nexora™, iNet provides a unified platform that connects field assets, ensures security, and drives intelligent operations across the upstream environment.

Challenges in Oil & Gas Connectivity

Common Challenge

Remote drilling and production sites far from fiber or cellular coverage.

iNet Solution

LEOConnect™ – Enterprise connectivity over Starlink and OneWeb, integrated with LTE for full-field coverage.

Common Challenge

Unpredictable network performance and downtime during operations.

iNet Solution

SecureLink™ – Private Layer-2 routing and QoS ensure uptime for SCADA, video, and voice. |

Common Challenge

Managing SCADA, IoT, and CCTV traffic across different transports.

iNet Solution

IntelliPath™ – SD-WAN intelligence dynamically optimizes application traffic across all links. |

Common Challenge

Lack of integrated network and surveillance systems.

iNet Solution

Construct™ – Field-proven design, deployment, and lifecycle management for hybrid networks and CCTV infrastructure. |

Common Challenge

Cybersecurity and visibility across remote networks.

iNet Solution

Sentinel™ – Continuous monitoring, intrusion detection, and managed firewall protection.

Common Challenge

Data visibility and decision support.

iNet Solution

Nexora™ – AI and analytics turning network data and video streams into operational insights.

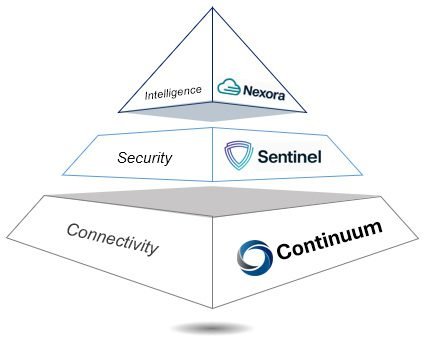

How the iNet Pyramid Powers Oil & Gas Operations

Top Layer: Nexora™ — Cloud, AI & Edge Intelligence

- Aggregates data from SCADA, sensors, and video streams.

- Delivers predictive analytics for well performance, equipment status, and site safety.

- Enables real-time visualization of operations across multiple basins or rigs.

Example: AI-based event detection from Axis cameras identifies equipment anomalies or safety events, generating alerts via Nexora dashboards.

Middle Layer: Sentinel™ — Security & Assurance

- Provides cyber and physical network security across field assets and HQ.

- Offers managed firewall, intrusion detection, and NOC visibility

- Integrates directly with CCTV and SCADA systems through SecureLink™.

Example: 24×7 monitoring of network health and security alerts for each rig and production site.

Core Layer: Continuum™ — Enterprise Connectivity Fabric

- LEOConnect™: Starlink and OneWeb for primary broadband across drilling rigs, frac fleets, and offshore platforms.

- SecureLink™: Private L2VPN to route SCADA, voice, and CCTV securely back to corporate networks.

- IntelliPath™: SD-WAN control ensuring high-priority traffic maintains predictable QoS.

A drilling contractor uses iNet Continuum™ to run real-time rig data, video surveillance, and voice communications over Starlink with secure private routing and automatic LTE failover.

Cloud, AI & Edge Intelligence

- Aggregates data from SCADA, sensors, and video streams

- Delivers predictive analytics for well performance, equipment status, and site safety.

- Enables real-time visualization of operations across multiple basins or rigs.

Example: AI-based event detection from Axis cameras identifies equipment anomalies or safety events, generating alerts via Nexora dashboards.

Security & Assurance

- Provides cyber and physical network security across field assets and HQ.

- Offers managed firewall, intrusion detection, and NOC visibility

- Integrates directly with CCTV and SCADA systems through SecureLink™.

Example: 24×7 monitoring of network health and security alerts for each rig and production site.

Enterprise Connectivity Fabric

- LEOConnect™: Starlink and OneWeb for primary broadband across drilling rigs, frac fleets, and offshore platforms.

- SecureLink™ : Private L2VPN to route SCADA, voice, and CCTV securely back to corporate networks.

- IntelliPath™ : SD-WAN control ensuring high-priority traffic maintains predictable QoS.

- Construct™ : Engineering, building, and managing hybrid LTE + LEO networks and CCTV systems across fields and platforms.

A drilling contractor uses iNet Continuum™ to run real-time rig data, video surveillance, and voice communications over Starlink with secure private routing and automatic LTE failover.

Onshore vs. Offshore Deployment Scenarios

Onshore Drilling & Production

- Private LTE and Starlink networks link rigs, tank batteries, and control centers.

- CCTV and sensor systems monitor HSE and production operations.

- Integrated NOC visibility through Sentinel™ for uptime and performance reporting.

Offshore Drilling & Production

- Multi-orbit Starlink + OneWeb access with SecureLink™ tunnels to corporate networks.

- CCTV coverage for deck and production areas integrated with Nexora™ for event detection.

- SD-WAN path optimization across satellite, LTE maritime backhaul, and fiber landing points.

Key Benefits

- Always-On Operations: Multi-path connectivity over Starlink, OneWeb, LTE, and private LTE.

- Operational Security: Fully encrypted L2 transport, CCTV visibility, and managed threat protection.

- Proven Performance: 99.9% uptime across hundreds of deployed rigs and production sites.

- Reduced Downtime: QoS routing ensures consistent SCADA, IoT, and voice communication.

- Simplified Management: One partner for network design, build, and management.

Connecting the Energy That Powers the World.